FAQs

RFID (radio frequency identification) linen tags, also known as RFID laundry tags, are small electronic devices that can be sewn into or attached to linens and textiles to enable tracking and identification.

RFID linen tags contain a tiny RFID chip and antenna that allow them to transmit data wirelessly to RFID readers. Each tag has a unique ID code that is detected when the tag passes within range of a reader.

In commercial laundry, hospitality, healthcare, apparel, and other industries, RFID linen tags are emerging as an efficient way to automate linen management processes. RFID linen tags provide visibility into the usage and status of tagged linens. This allows organizations to optimize linen inventories, prevent loss, increase turnover efficiency, and improve customer service.

RFID linen tags are designed to withstand repeated industrial laundry processes involving very high temperatures, detergents, bleaches and various mechanical stresses. HLT laundry tags are qualified, robust, flexible and soft for fitting all kinds of textiles. Rigid, and robust enough to suffer heavy physical strength and pressure; heat resistant for over 180°C in washing in detergent, and over 210°C ironing; last through at least 200 wash cycles.

RFID linen tag is an ideal device for tracking and tracing textiles assets. Welcome to contact us to get more about automating your linen tracking through RFID technology.

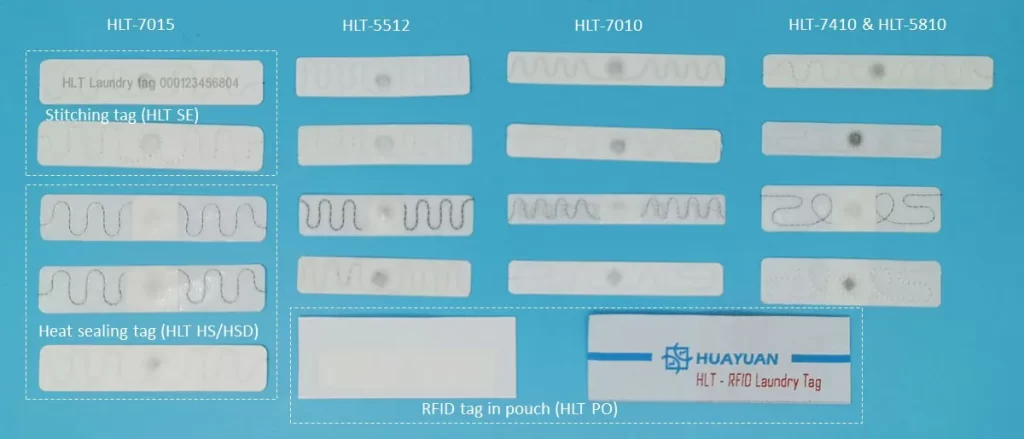

TEXBIT offers RFID linen tags in a variety of sizes to suit different types of linens and textiles. Common sizes: 36*15mm(HLT-3615), 55*12mm(HLT-5512), 60*12mm(HLT-6012), 70*10mm(HLT-7010), 70*15mm(HLT-7015), 74*10mm(HLT-7410).

More details as below:

| HLT Serial Laundry Tag Format | HLT-3615 | HLT-5512 | HLT-6012 | HLT-7015 | HLT-7010/7410 | NOTE | |

| Tag size | 36x15mm | 55x12mm | 60x12mm | 70x15mm | 70x10mm 74x10mm | More sizes are available | |

| Reading Range @30dbm | 2.0mts | 5.0mts | 6.0mts | 8.0mts | 8.0mts | up to 30% weak after 200cycles laundry | |

| Type | Double Layers for Stitch | Yes | Yes | Yes | Yes | Yes | Typical format |

| Heat Sealing | Yes | Yes | Yes | Yes | N/A | Soft, touchless | |

| Double Layers for Heat Sealing | Yes | Yes | Yes | Yes | N/A | Robust, suitable for PPE. | |

| Pouch | Yes | Yes | Yes | Yes | Yes | Logo weaved | |

| Optional Tiny 3.5×3.5×0.8mm Module | Yes | Yes | Yes | Yes | Yes | Thinner and tiny chip module | |

| Code / QR / DataMatrix Laser Printed | Yes | Yes | Yes | Yes | N/A | Variable data processes with TID collection | |

For specialized applications, we can provide custom RFID linen tag sizes tailored to your exact specifications.

Contact us to discuss your RFID linen tagging needs.

TEXBIT offers several options of RAIN RFID Laundry Tag to apply on textiles. Determining the best selection depends on the textile type and the laundry processes. Our experts willing to assist you for your application.

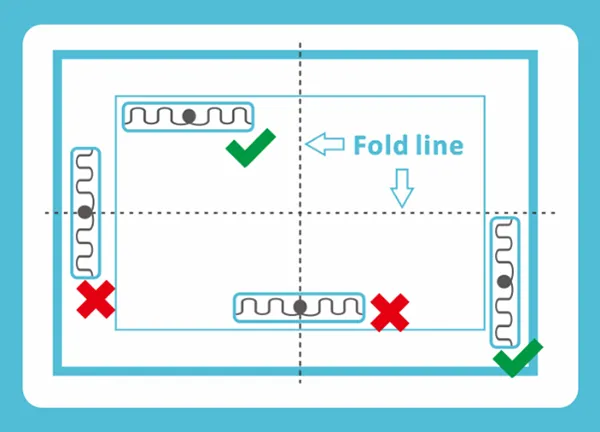

Tips to help get the best possible results:

- In order to not affect the RFID laundry tag’s performance, install the tag away from the textile folding lines, close to the textile corners.

- Seams must NEVER pass through transponder’s central core module.

Stitch Tagging (SE) // HLT-5512-SE / HLT-7015-SE

To be stitched into the hem of a textile.

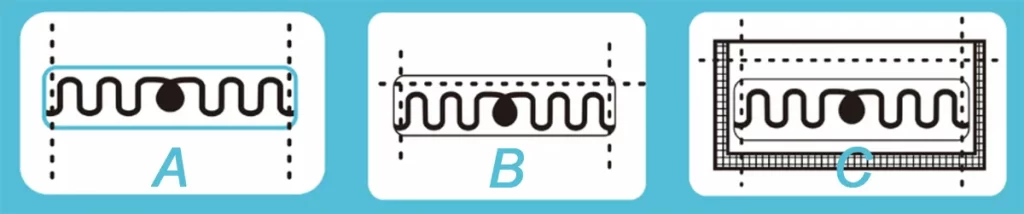

* How to stitch?

1, Place the laundry tag inside the textile. Sewing lines surround tag’s extremities.

2, Stay less than 5mm from the tag’s edge when stitching.

3, Pay special attention to not damage your sewing facility if you stitch over the antenna wire extremities. Stitch must NEVER pass through the core module.

* Where to stitch?

A. Stitching at both ends of tag, avoid crossing the metal antenna line.

B. Sewing three sides without pricking the metal antenna of horizontal long side.

C. Putting the tag into a pouch/pocket.

Heat Sealing (HS) // HLT-5512-HS / HLT-7015-HS

The max. temperature for iron and heat-seal is +210°C (410°F) by 0.6MPa~0.8MPa pressure for less than 18 seconds, and the ironing pressure should be concentrated on the tag.

* How to heat-sealed?

1, Place clean and dry textiles under the heat-sealing machine.

2, Place the adhesive side of the tag on textile flat surface, avoiding any relief and folding lines.

In Pouch (PO) // HLT-5512-PO / HLT-7015-PO

To be stitched like a standard care label.

* How to stitch?

Place the pouch BELOW the hem. Fix the pouch BELOW the hem. Fix the pouch one along each side. Stitches must NEVER pass over the laundry tag’s antenna wire or the core module.

* Where to stitch?

Stitch the laundry tag away from the folding lines.

When choosing an RFID tag for commercial laundry applications, certifications & test reports are key to ensuring the tag will withstand the demanding laundry environment. Our HLT laundry RFID tags have obtained these certifications that demonstrate their exceptional quality, safety, and reliability.

1. OEKO-TEX STANDARD 100

The OEKO-TEX STANDARD 100 certification is a renowned international standard that evaluates and restricts the use of harmful substances in textile and apparel products. Our HLT laundry tags are certified to OEKO-TEX Standard 100, indicating they are tested and confirmed to be free of harmful substances. This gives textile suppliers, laundry operators, and end-users confidence that HLT tags are safe for employees handling the laundry as well as safe even when in direct contact with skin.

2. Eurofins Color Fastness

Eurofins testing confirms excellent color fastness for HLT laundry tags, with ratings up to 4-5 on the 5-point gray-scale for factors like crocking, light exposure, and washing. This ensures the tag color remains vibrant even after repeated industrial laundry cycles.

3. SGS

SGS testing and certification is highly regarded worldwide for verifying product quality. HLT linen tags have obtained SGS certification, demonstrating they compliance the SGS standards.

4. ATP Certificate of EECC

The EECC (European EPC Competence Center) ATP (Applied Tag Performance) certificate means the HLT laundry tag has passed testing for production consistency, read ranges on materials and in proximity. The ATP testing verifies the stable performance of tags.

5. POPs

The POPS (Persistent Organic Pollutants) test ensures compliance with regulations regarding specific hazardous substances. Our product, the HLT laundry RFID tag, successfully passed the following criteria:

- Short Chain Chlorinated Paraffin (SCCP): Our product meets the requirements for SCCP content.

- Hexabromocyclododecane: Our product adheres to the regulations outlined in Commission Regulation (EU) No 2016/293 and Regulation (EC) No 850/2004 concerning Hexabromocyclododecane content.

6. RoHs

The RoHS (Restriction of Hazardous Substances) test verifies the absence of certain hazardous substances in electrical and electronic equipment. Our product passed the screening test conducted by XRF Spectroscopy, ensuring compliance with RoHS (recast) Directive 2011/65/EU Annex II and its amendment.

7. REACH

The SVHC (Substances of Very High Concern) test screens for substances listed by the European Chemicals Agency (ECHA) as SVHCs, ensuring compliance with Regulation (EC) No 1907/2006 and its amendments. Also known as REACH testing. Our product successfully passed the screening for substances of very high concern subject to the candidate list, meeting the requirements set forth by the European Chemicals Agency.

With certifications and test reports from renowned testing organizations, HUAYUAN assures customers its HLT laundry tags deliver outstanding performance you can depend on. The rigorous certification testing reflects HUAYUAN’s commitment to quality and continually innovating better solutions.

Welcome to contact us to get samples for testing our laundry RFID tags in your industrial washing environment.