Our Products

RFID Linen Tag

TEX-BIT RAIN RFID laundry tag is a flexible, tenacious, and heat, pressure & stretching resistant fabric-made RFID transponder for textile asset lifecycle tracking purposes. All textiles like flat linens, workwear, and uniforms can be traced and tracked imperceptibly by a unique ID carried in tag, to realize digital transparency and touchless laundry management throughout the soil collection, laundering, distribution processes by RFID facilities connected with IT management systems synchronously. The RFID laundry chip can be inserted into the tiny flat linen as well as finest textiles with no-wear feeling and unnoticeable look.

Washable Ultra-soft RFID Care Label

The washable ultra-soft RFID care label is more than just an RFID tag—it’s a sustainable, durable, and flexible solution designed to meet the evolving demands of the textile industry. From high-end fashion to efficient supply chain management, this care label empowers brands to innovate while maintaining a commitment to quality and environmental responsibility.

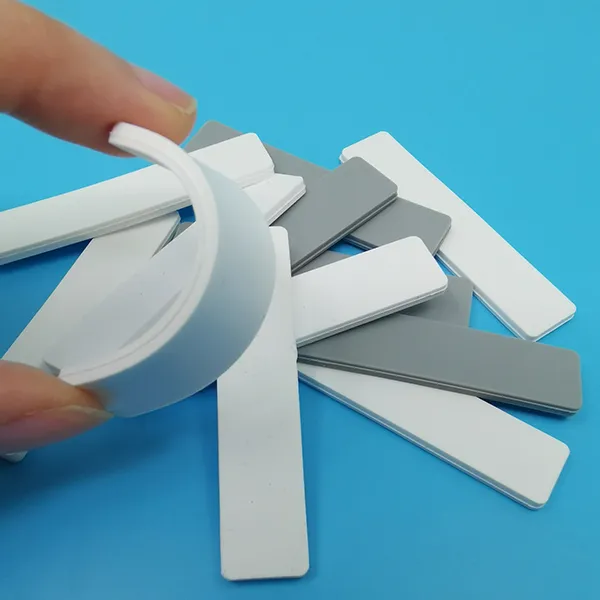

RFID Silicone Laundry Tag

The Silicone RFID laundry tag is soft and durable, which can be applied to the washing environment such as continuous high-pressure dehydration and ironing in a short time. Silicone laundry chips use UHF technology to effectively improve communication performance. Reading hundreds of tags at a time can reduce labor costs caused by barcodes or HF (high frequency) RFID tags and provide cost-effective management.